SCHULTHEISS VPC040 Casting Machine

Description

Compact Vacuum Pressure Jewellery Casting Machine created specially for Designer Goldsmiths and Smaller Studios.

Featuring a combination of technologies that have normally been available only in larger size high production machines, the VPC-040 provides for exceptionally high quality castings time after time at the touch of a button.

It’ s modest footprint only 500mm wide x 580mm deep x 560mm high allows for high-tech casting even in tight workshop space and with its stylish European design, it doesn’ t need to be hidden from your clients view.

Perfectly suited for casting from 2 to 20 rings in ● Gold ● Silver ● Palladium Alloys

What are these technologies and why would you want them?

The standard VPC-040 provides…

Programmable Control of up to 10 different Casting Parameters 1 - At the touch of a button you can reproduce exceptionally high quality castings time after time! Built-in memory for 50 programmed combinations of the 7 casting parameters allows you to personalise your machine for the individual alloys you use and to suit the various types of jewellery you wish to cast from very fine filigree to larger flat surfaces or any point between.

( 1 Choose from 2 power options VPC040 Power - 5.0kw program automatic 10 paramaters or VPC040 Classic - with 3.5kw automatic 4 paramaters)

Digitally Controlled Induction Melting under Protection Gas - Eliminate cold porosity - produce even density castings - avoid oxidation of the metal - shorten cycle times. The melting system allows you to set an exact casting temperature and produce a completely homogenous blend of alloy ready to cast in just a few minutes with an inert gas protecting the melt from oxidation.

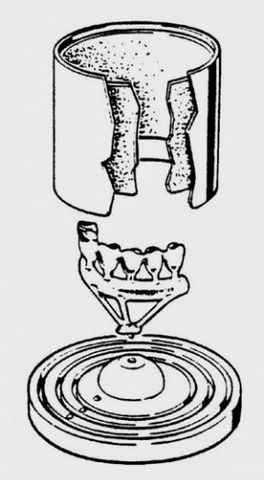

Vertical Casting System under Vacuum - Avoid impurities in the castings. The molten metal is drawn straight from the bottom of the crucible directly into the vacuumed flask chamber leaving any impurities that were on top of the melt in the button.

* Optional Extras available to suit your requirements

* Pressure Differential Casting System - Provides for complete fill of ultra fine filigree parts and aides stone-in-place casting. Gas pressure from above the melt combined with the vacuum below forces the metal into place very quickly even if your investment has little permeability. Silver and White Gold castings in particular benefit from this feature.

* Melt Treatment and Metal Degassing - Super Silver avoids oxidation (blue silver) This feature is an option for those workshops producing Silver and other metals without volatile alloy parts to degas the alloy during the melting process.

* Flask Vibration System - Produces more even, higher density castings. This feature is an option that provides control over flask vibration during and/or after pouring for grain refining to reduce the possibility of fissures and porosity and is very useful if your alloy does not already contain grain refiner.

* Integrated Printer / RS232 - Automated recording of your casting operations. This feature is an option to provide serial connection to printers of computer systems for recording your casting operations.

* Mixing Booster - Mix your own alloy. For those who like to have a special mix to their own recipe, the mixing booster ensures a completely homogenous blend of alloy.

* Optic Temperature Automatic - For casting in Platinum. This option also requires High Temperature Preparation and is suitable for occasional casting in Platinum. This is not suite