- Home /

- Casting, Melting & Waxes /

- Casting Machines & Accessories /

- Dentalfarm Induction Casting Machine - EC-1

Shop Now

- Articulating Papers, Foils & Sprays

- Articulators, Jigs & Models

-

Burs & Polishers - Surgery

- Accessories

- Bur Kits

- Burs - Crown Cutters

- Burs - Crown Prep

- Burs - Diamond

- Burs - Endodontic

- Burs - Periodontic

- Burs - Steel

- Burs - Surgical

- Burs - Tungsten Carbide

- Ceramic & Composite Abrasives

- Ceramic Polishing

- Composite Polishing

- Diamond Finishing Strips

- Gold & Amalgum Polishing

- Mandrels & Adaptors

- Prophylaxis Polishers

- Monthly Specials

- Clearance

- Burs - Laboratory

- Casting, Melting & Waxes

- Catalogue

- Ceramics

- Chairs, Tools & Accessories

- Cleaning

- Dust Collection & Air Filtration

- Flex Shafts & Micromotors

- Handpieces

- Instruments & Tools

- Lighting & Photography

- Magnifiers

- Measuring: Gauges, Scales

- Microscopy

- Model Finishing

-

Polishing & Abrasives

- Abrasive Bands, Discs, Paper, Sticks & Wheels

- Acrylic Polishing & Trimming

- Ceramic Polishing & Trimming

- Chrome Polishers

- Composite Polishing & Trimming

- Diamond Discs

- Gold & Metals Polishers

- Kits

- Mandrels, Pins & Adaptors

- Mounted Abrasives

- Mounted Stones

- Polishing Brushes & Mops / Buffs (Lathe)

- Polishing Brushes & Mops/Buffs Mounted

- Polishing Compounds

- Polishing Lathes, Extractors & Accessories

- Polishing Sets & Other

- Separating & Grinding Discs

- Monthly Specials

- Clearance

- Safety

- Sandblasting

- Soldering & Welding

- 3D Printing

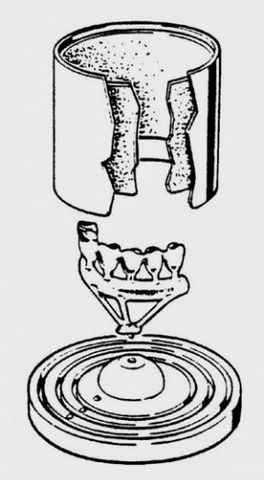

Dentalfarm Induction Casting Machine - EC-1

Description

Medium frequency electronic induction casting machine, suitable for melting all dental alloys (except titanium and pure platinum).

Medium frequency induction along with the ability to measure the power output allow the user to work with each type of alloy under the best conditions. Casting by means of electronic induction means progressively heating the metal from the inside outwards. This results in a continuous mixing of the alloy various components thanks to the rotating motion of the magnetic field. The accomplished liquefaction is evident as the melt mass tends to « rise» inside the crucible. Injection by centrifugation ensures maximum molecular compactness as it has been recognized as the only system capable of maintaining the material under high pressure until the solid state is achieved.

CHARACTERISTICS

Control over rated power allows the user to work quickly on alloys featuring high melting temperatures which tend to oxidize easily, as well as for gentle and slow handling when casting precious metals thus preventing them from sublimating

Extremely use to use thanks to the logical and incommutable scanning of operating functions

Steady supervision of all important parameters: in case of insufficient safety conditions, prosecution of the melting process will be inhibited

Display repeatedly showing the parameters of the working cycle or the precise description of any irregular condition

Visual inspection of the metal process through a protective screen

Stainless steel centrifugation chamber for easy cleaning

Injection achieved by centrifugation provides for high molecular compactness and superior results with any alloy

Acceleration, speed and rotating time parameters are freely adjustable

Built-in water cooling system controlled by a thermostat and pressure switch

Restricted energy consumption, no preferential electric line is required

Possibility of connection to an inert gas cylinder for increased protection throughout the melting area

Overall dimensions: mm 500x700x1060h

Power: 2,860W

Similar Products...

-

50% OffWas:$32.39 ex gstNow:$16.33 ex gstPrice:$16.33 ex gst$32.39 ex gst$16.33 ex gst

-

50% OffWas:$386.20 ex gstNow:$177.35 ex gstPrice:$177.35 ex gst$386.20 ex gst$177.35 ex gst

-

50% OffWas:$386.20 ex gstNow:$177.35 ex gstPrice:$177.35 ex gst$386.20 ex gst$177.35 ex gst